The best raw materials, experience, technology, and strict process control are necessary to get a high-quality armored glass. Easy installation, great finish, durability and excellent Optics save money and add value to the armored vehicle.

Traceability and control. Software and technology.

Our Optima Enterprise software lets us know exactly what is happening to your glass.

- Exact and personalized information, necessary to make the glass that you need.

- Record and control of each part in real time during the whole process.

Stable Processes

At Optima we don’t experiment with our clients. We incorporate materials and technologies that have proven effective and create and advantages for our clients.

We utilize formulas with 100% Polyurethane (PU) as the only adhesice material to prevent delamination and the haze effect; we automate processes like cutting and polishing using CNC machining centers, to achieve accurate dimensions.

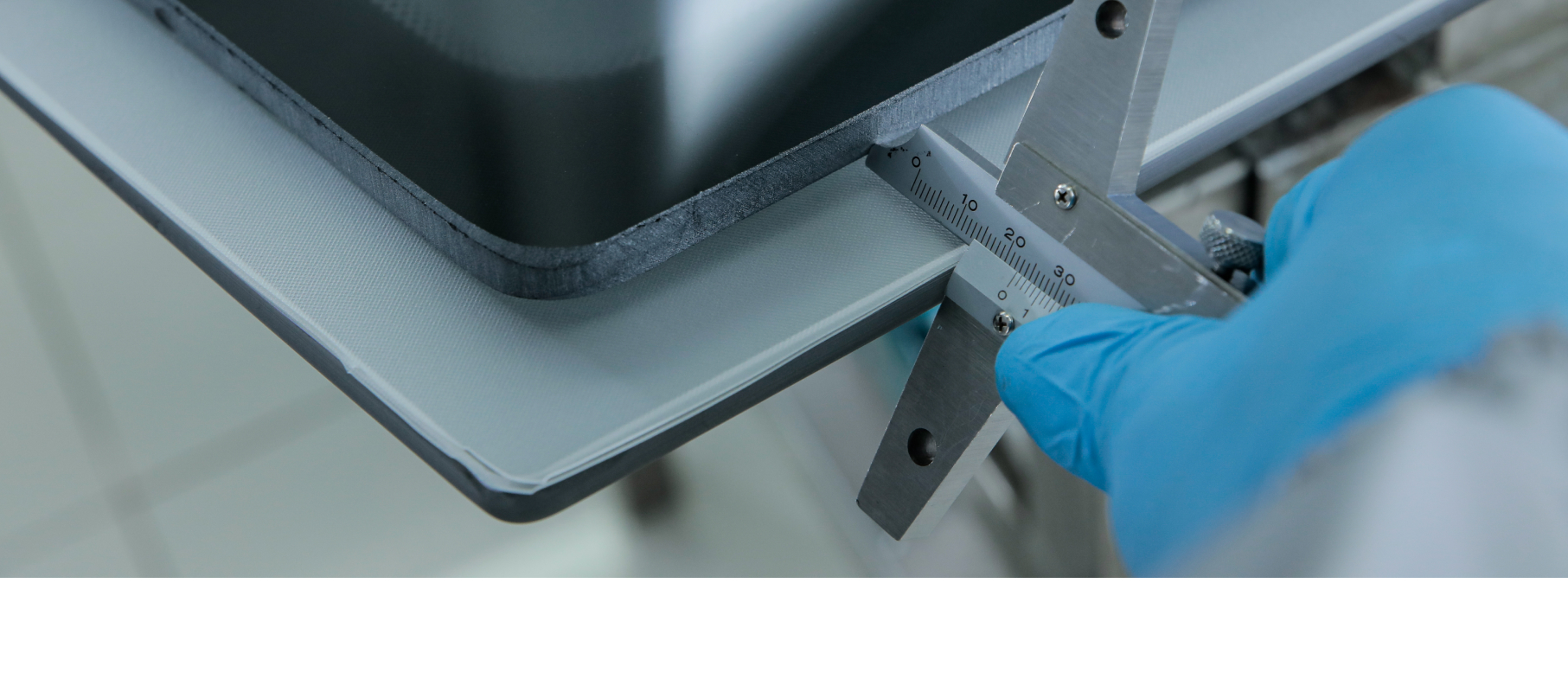

Dimensional stability

Transparencies can have invisible problems that show up during the mounting process and/or the use of the vehicle.

Installation difficulty, marks when raising or lowering the window, wind noise when driving……are effects of poor dimensional control.

At Optima we stabilize our processes to offer great reliability and durability.

Optical Quality

Beyond safety… for the end user, high quality armored glass means a discreet vehicle, driving comfort and great visibility.